Introduction

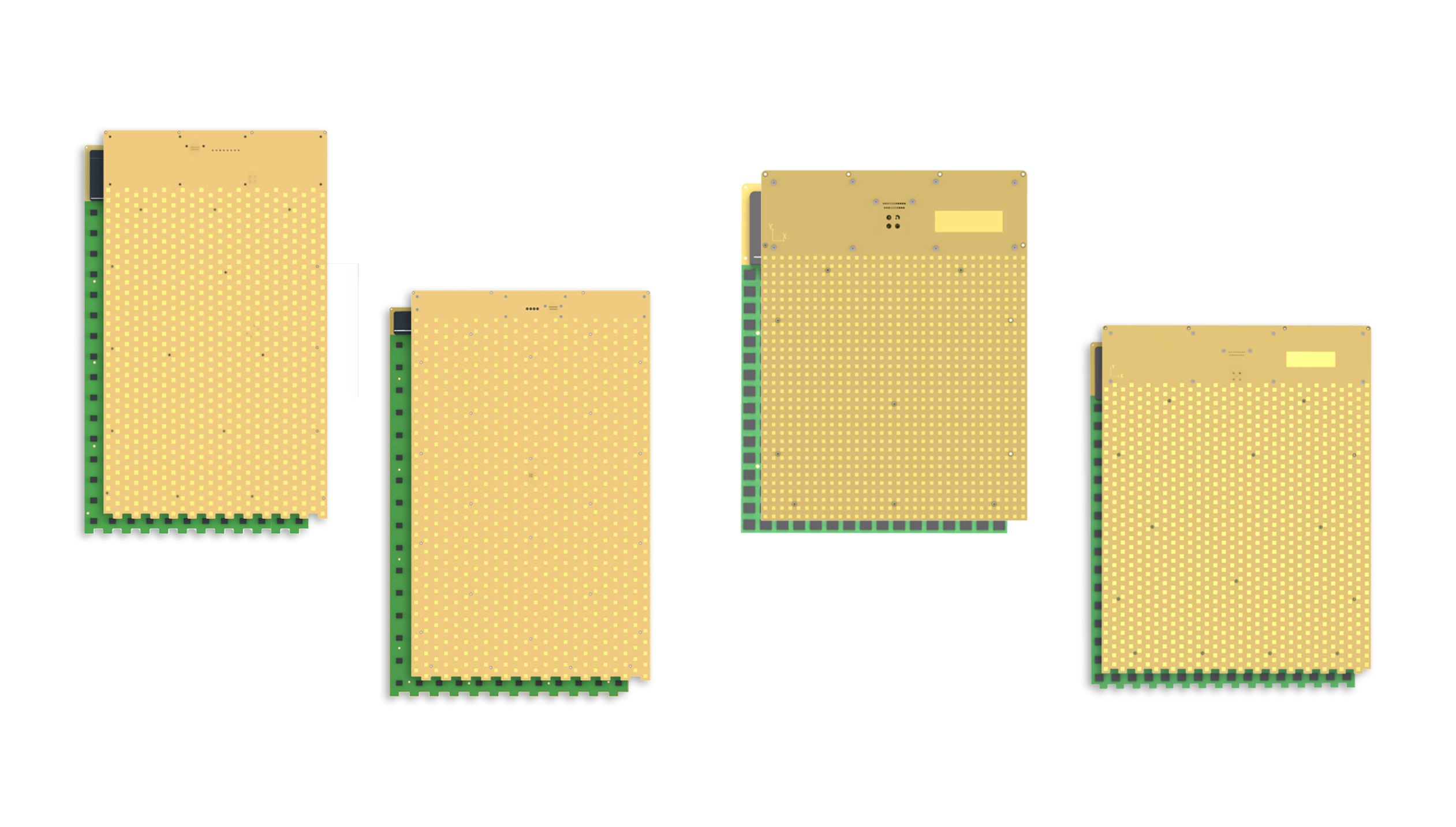

In order to bring AESA technology to the market as soon as possible, and make AESA technology easy to use and affordable. XPHASED combined cost, performance, manufacturing difficulty and other perspectives, several PANEL products have been carefully designed, but the needs of partners are infinitely possible. Therefore, we welcome partners to propose various CUSTOMER designs to us. On the other hand, XPHASED can also provide technical support to support partners in designing various panels.

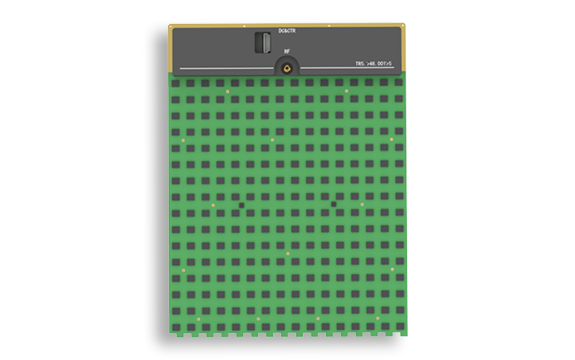

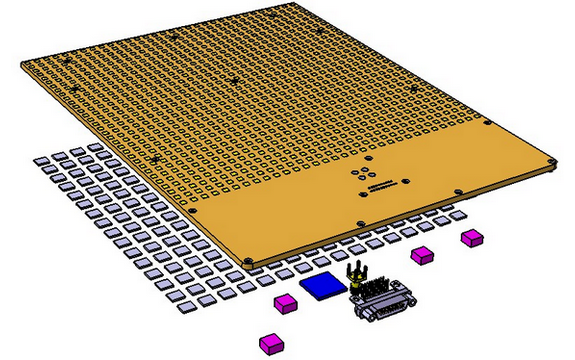

Pictures of the product

TenSu-SA1T is compact in design, extremely low profile, free of any mechanical moving parts, capable of swift beam pointing updating in large airspace, and sturdy and durable. TenSu-SA1T allows to create larger-aperture phased array antenna by combining multiple arrays, and meets the unique performance needs of the customers by fast iteration of array combinations without starting all over again to design a new antenna.

TenSu-SA1T adopts industrial grade components, and its operating temperature range is - 40℃~ +85℃. TenSu-SA1T supports a wide input voltage range of +9 ~ +32V, and its power consumption at P-1 point is not more than 100W.

Features

· Single-beam 2D electrical scanning active transmit phased array;

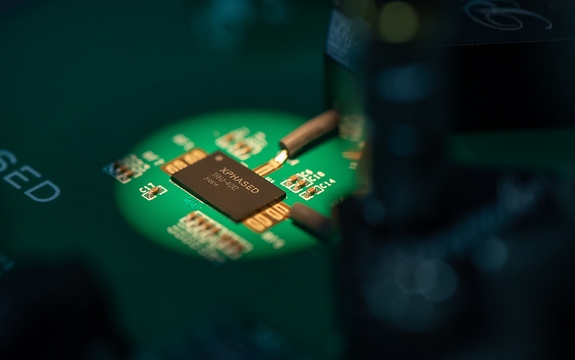

· Leveraging SOC with independent intellectual property rights;

· EIRP: 40dBW (at boresight, center frequency and P-1);

· Supports LHCP and RHCP, switchable within 0.5ms;

· Adopts advanced beamforming algorithm, enabling pointing switching time < 250us;

· Elevation angle: 30°-90°;

· Ultra-thin & light, 160mm×210mm×12.3mm (W*L*H), 0.36kg;

· Calibrated, easy to install, plug and play;

· Scalable to form large-scale antenna array;

· Integrates real-time temperature monitoring and power-on self-test functions;

· HDLC-RS422 for control interface;

· RoHS 2.0 certification.

Applications

Satellite communications;

Microwave backhaul;

Point-to-point communication;

Signal reconnaissance/interference.

How to use it?

TenSu-SA1T operates in Ka-band and it is a printed circuit board hosting 1024 antenna elements for transmit, 256 beam former chips, feed networks, driver chips, beam control circuit, power supply circuit, etc. The signal phase and amplitude of each antenna array element are instantly changed, which is realized by the real-time computing function provided by FPGA, and the small signals radiated by all the array elements converge in a specific direction to instantly form arbitrary directional beams.

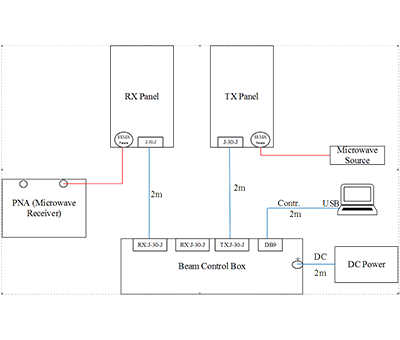

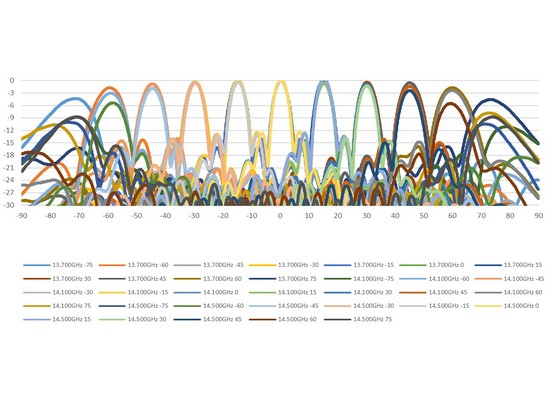

Panel test suite introduction

Test condition requirements

The panel test needs a chamber test environment, and the high-precision turntable table equipped with control software to provide full profile test platform, and DC power supply equipment, vector network analysis, spectrum analyzer and other equipment are needed to conduct a comprehensive panel performance test.